Nested Based Manufacturing

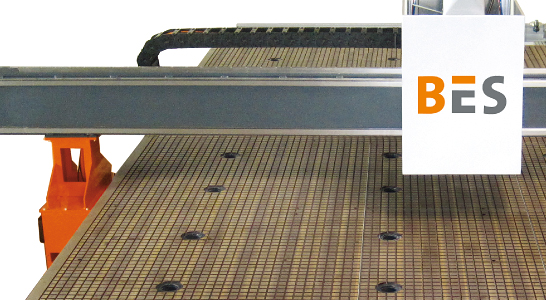

New vacuum table technology ›Air Save‹

The new optimized vacuum allocation technology ›Air Save‹ improves the security of the workpiece clamping, therefore for the production process and reduces the expenditure of energy by minimizing vacuum volume. The machine table is divided into a large number of identical vacuum segments. Each field can be ventilated by a valve or shut off immediately. This structure supported by a modified cutting-order optimize the use of the suction air. The individual workpiece are not sized in the line modus rather per field.

Are the workpieces in a field are finished, the valve closes the vacuum line. The remaining fields are now again processed with the entire vacuum volume maintaining high pressure and avoiding false air.

The BES vacuum optimization is particularly energy efficient. In traditional nesting machines the operation requires more vacuum pumps, and it is manufactured from the start with an excess capacity to prevent a displacement of the workpieces. Competitor with a comparable machine, use two vacuum pumps with 7.5 kW each one, BES only requires a vacuum pump with 4.5 kW for the Multi-Cut Center.